Hydrogen Research

Fuel:

The conversion to hydrogen based fuels and energy storage within the next 40 years

was identified as a national priority: for example, the President’s 2007 budget will

provide $289M to accelerate the development of hydrogen fuel cells. In the near term

systems that specialize in the integration of renewable energy with hydrogen storage

and fuel cells show great promise. Renewable energy sources frequently depend on climate

and weather conditions and hence are intrinsically intermittent. Hydrogen provides

a means to store renewable energy for later use with fuel cells.

The conversion to hydrogen based fuels and energy storage within the next 40 years

was identified as a national priority: for example, the President’s 2007 budget will

provide $289M to accelerate the development of hydrogen fuel cells. In the near term

systems that specialize in the integration of renewable energy with hydrogen storage

and fuel cells show great promise. Renewable energy sources frequently depend on climate

and weather conditions and hence are intrinsically intermittent. Hydrogen provides

a means to store renewable energy for later use with fuel cells.

The center will coordinate research efforts among federally funded programs already ongoing at Stony Brook, SUNY Farmingdale, and BNL on biomass and micro-organism generation of hydrogen, nanostructured ion exchange membranes for hydrogen processing, high power density miniaturized fuel cells, biomimetic fuel cells, and self assembled nanostructures for ultra high capacity hydrogen storage. The amount of methane gas that is tied up as hydrates beneath the seafloor and in permafrost is several orders of magnitude higher than all other known conventional sources of methane and is sufficient to meet our energy needs for several decades. The characteristic instability of methane hydrates ice-like cages made of water molecules surrounding individual methane molecules are only stable under certain temperature (< 20ºC) and pressure (> 2MPa) conditions -- provides a technological challenge to efficient mining and safe transport. Hence a large interdisciplinary collaboration among various groups at BNL and Stony Brook has already been established in order to study the kinetics of methane hydrate formation in underwater sediments and develop methods for mining this abundant natural resource.

Fuel Cells:

Solid oxide fuel cells (SOFC) in combination with hydrate integrated systems can form

an extremely efficient version of SOFC where waste heat from the internal reactions

can be used for thermal recovery of hydrates. Another commonly used fuel cell, the

Polymer Electrolyte Membrane (PEM) fuel cells, also called Proton Exchange Membrane

fuel cells are popular for automotive applications which require high power.

Solid oxide fuel cells (SOFC) in combination with hydrate integrated systems can form

an extremely efficient version of SOFC where waste heat from the internal reactions

can be used for thermal recovery of hydrates. Another commonly used fuel cell, the

Polymer Electrolyte Membrane (PEM) fuel cells, also called Proton Exchange Membrane

fuel cells are popular for automotive applications which require high power.

A PEM fuel cell uses hydrogen fuel and oxygen from the air to produce electricity. The PEM fuel cell system represents an alternative power source to traditional, combustion-based technologies and batteries. In practice, fuel cells are connected through the bi-polar plates to form a fuel cell stack to provide high power. Good performance of the stack requires high electrical and thermal conductivities of plates, ease of distribution of fuel, oxidant, residual gases, and water without leaks, ability to withstand mechanical loads during operation, and high resistance to corrosion when in contact with an acidic electrolyte, oxygen, heat and humidity.

The Center for Fuel Cell Development at SUNY Farmingdale has developed new aluminum bipolar plates with protective corrosion resistant coating for PEM fuel cell power stacks. This innovative technology for metallic power stacks is much safer, more efficient and more economical than the graphite plates that are commonly utilized as the standard material for the PEM bipolar plates. This new technology provides at least a 12% savings in hydrogen consumption because of lower resistive losses which occur when aluminum rather than graphite coated surfaces are used.

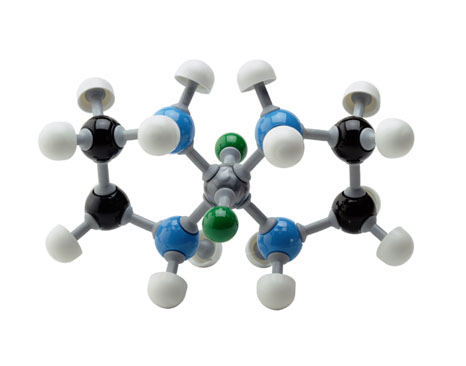

Design of high performance cells can also be achieved through molecularly engineered membranes, which incorporate catalytic nanoparticles of platinum or palladium. These particles are resistant to corrosion, yet their high surface to volume ratio and quantum structure renders them highly efficient in hydrogen storage. Research at Stony Brook in collaboration with the BNL/CNF has shown that these particles can be incorporated into polymer electrodes that are malleable, permeable to hydrogen and yet highly conducting. Further research in the design and implementation of these advanced nanocomposites, with polymers that can withstand extreme conditions, while communicating internal conditions with continuous self diagnosis, can make these cells a commercial reality.